THERMAL INSULATION FOR EXTERIOR WALLS USING FF-PIR POLYURETHANE INSULATION PRODUCTS

FF-PIR is one of the most effective thermal insulation materials available on the market with a declared thermal conductivity (λDeclared) of 0.022 W/mK. FF-PIR insulation products are suitable for new construction, low-energy, passive and zero-energy construction houses, and for supplementary thermal insulation of older buildings.

FF-PIR insulation can be used to create very thin and leak-proof structures. In constructing low energy, passive, or zero-energy houses, structural thicknesses will barely increase when compared to conventional houses built using traditional insulation products.

When used in the ventilated facades of P1 fire class apartment buildings, FF-PIR FR improves the safety of the structure substantially, as the flame retardant FR laminate on the surface of the panels expands to fill the ventilation gap and thus prevents fire from spreading through.

Ventilated facades for P1 buildings less than 28 meters high can also be created using FF-PIR AL insulation products in accordance with separate fire performance testing.

COMBINATION OF INSULATION AND VAPOR BARRIER

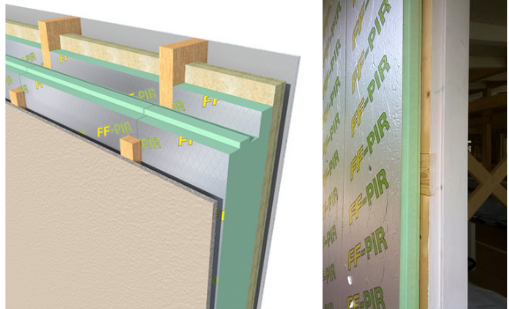

Separate air or vapor barriers are also not necessary in the structures. The aluminum or plastic laminate on the surface of the FF-PIR insulation products has a very high water vapor resistance and also functions as vapor barrier within structures. For the seams and joints between the panels, we recommend using elastic foam sealant and vapor barrier or aluminum tape that is suitable for joints.

FF-PIR insulation products are excellently suited for use with different frame materials in roofs. The frames can consist of wood, steel, concrete, or lightweight concrete (Siporex).

In a zero-energy house, the frame structure can be protected from weather by installing a sufficiently thick and effective layer of thermal insulation on the outside of the framework of the building.

FF-PIR INSULATION PRODUCTS ARE SUITABLE FOR ALL FRAME STRUCTURES

FF-PIR insulation products can be used in exterior walls with various framework materials. When the framework is made from wood, the structure can be constructed as a so-called full PIR wall, where a 100 or 150 mm FF-PIR K600 panel is installed between studs with on-center spacing of 600 mm (K600). A second continuous layer of panels is installed on the inside or outside of the structure. If the second layer is installed on the inside, its thickness may be chosen freely based on suitability for the project (30–150 mm). Where the second layer is installed on the outside of a load-bearing framework, the exterior insulation must be as thick or thicker as the FF-PIR insulation in between the framework elements to insure proper moisture performance.

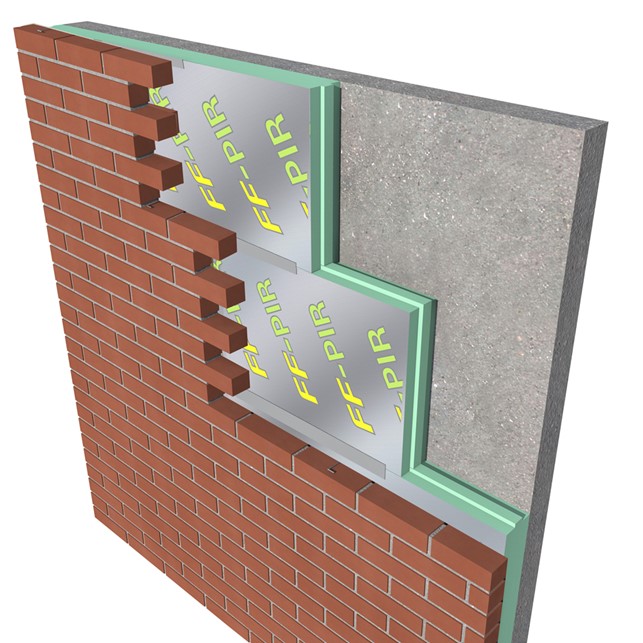

Ventilated facade FF-PIR FR.

INSULATION THICKNESS BASED ON THE U VALUE

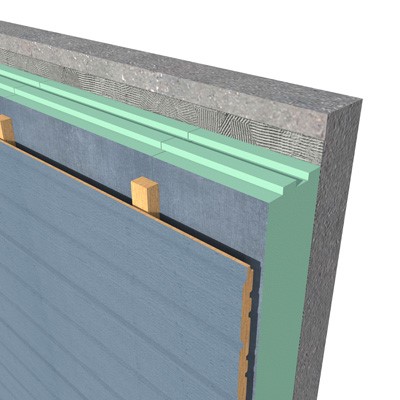

In a so-called hybrid structure, wind-proofing is installed on the outside of the studs as regular, mineral wool insulation is fitted between the studs, and a continuous layer of FF-PIR insulation panels is installed on the inside with the seals seamed with elastic foam sealant and tape. The thickness of insulation is determined according to the desired U value. This will create an absolutely leak-proof and energy efficient structure.

The framework of the exterior wall can also consist of concrete, brick, or breeze blocks, in which case insulation panels are installed as a continuous layer on the outside of the internal framework.

The FF-PIR PLI insulation products are used where the insulation becomes into contact with poured concrete as they are suitable for use with fresh concrete.