Thermal Insulation–DURABLE AND WATERPROOF

Our insulation is an XPS thermal insulation product made from extruded polystyrene, which retains its insulating capacity in even the most demanding conditions. The panel’s special feature is its completely closed and consistent cell structure, which ensures a high insulating capacity and impermeability. In addition to thermal insulation, FINNFOAM also facilitates various other construction stages, thus enabling high-quality and energy efficient results. Structures produced using FINNFOAM do not require separate vapor barriers or wind-proofing panels, which means that a single installation takes care of several work elements. FINNFOAM is also mold-proof, as verified by VTT using the most stringent mold testing available.

VERSATILE INSULATION – FROM PIPE TRENCHES TO ATTIC ROOFS

The entire range is suitable for use as frost insulation and for insulating floors, roofs, and walls, as well as various types of supplementary thermal insulation. As frost and floor insulation, FINNFOAM is highly resistant to moisture, freezing, and load. After all, reliability is the most important property of frost insulation, and its insulating properties cannot be allowed to deteriorate over time. The freeze-thaw-resistance of frost insulation products should always be specified. A prime example of FINNFOAM’s reliability is the first place it claimed in a frost insulation comparison conducted by the TM Rakennusmaailma magazine in the fall of 2011.

For almost 40 years, FINNFOAM has been relied on for various demanding applications ranging from train tracks to public buildings, shopping centers, and industrial facilities. We also provide excellent solutions for the construction of business premises, housing, low rise buildings, and infrastructure.

This section provides information on FINNFOAM thermal insulation products and their properties. The Applications section includes specific information on using the products for different applications.

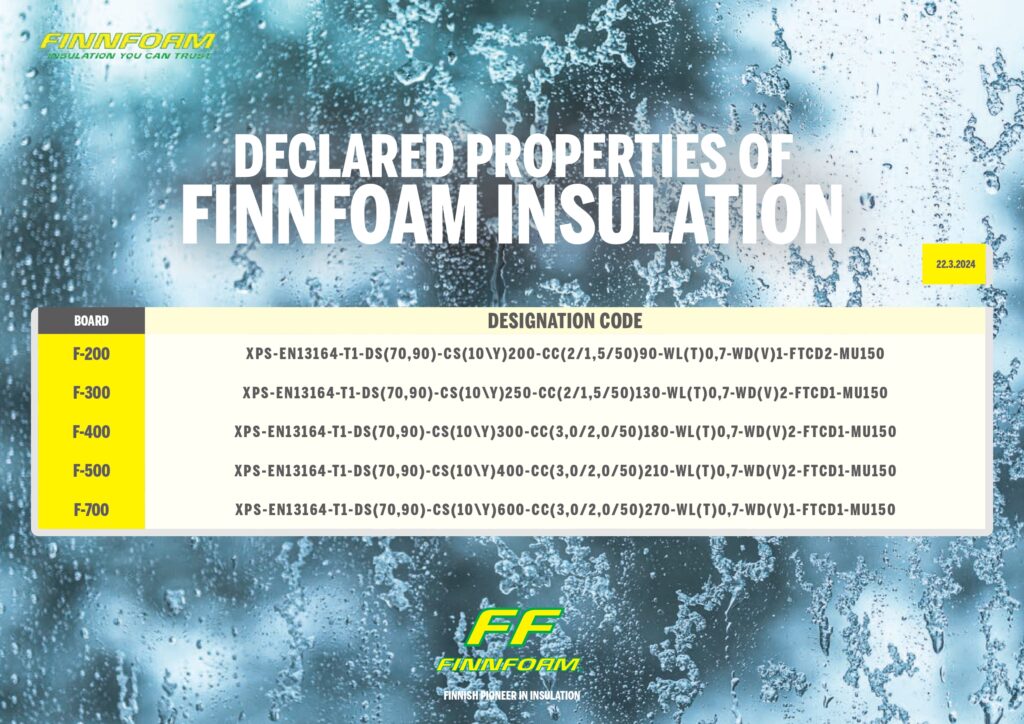

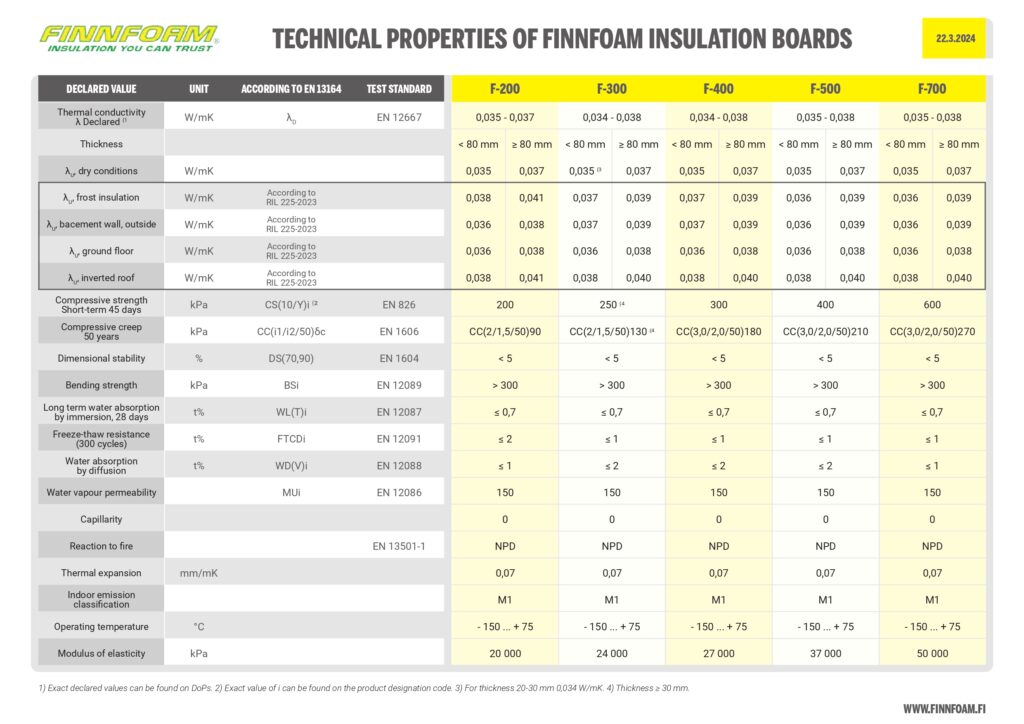

TECHNICAL PROPERTIS OF FINNFOAM INSULATION BOARDS

STANDARD PANEL DIMENSIONS AND TYPES

INNFOAM is an exceptionally versatile thermal insulation product. The same standard insulation panels can be used for various applications and purposes ranging from frost protection to base floors, intermediate floors, ceilings, walls, supplementary thermal insulation, etc.

NEW PRODUCT! The range now includes thicker standard panels as well (FI and FL), up to 300 mm. Using thicker panels reduces the amount of layers that need to be installed, thus speeding up work at the worksite significantly.

Panel size:

Flat edge, FI: 600 × 2 500 mm = 1.50 m2

Rabbet, FL (effective dimensions): 585 × 2 485 mm = 1.45 m2

Thickness: 20 – 300 mm

Fire class: NPD

Material: Extruded polystyrene (XPS)

Cell structure: Consistent and closed, does not absorb water

COMPOSITION AND STRUCTURE

COMPOSITION

FINNFOAM is a cellular plastic made primarily from polystyrene. Polystyrene is not hazardous to health. Polystyrene is widely used as packing material for foodstuffs. Polystyrene is a thermoplastic material that can be melted down and reused.

The other main raw material used in the production of FINNFOAM expanded polystyrene products is carbon dioxide, which is sourced, among other things, from industrial emissions, and is thus environmentally friendly. Carbon dioxide escapes from the panels and is replaced with air within a few weeks of manufacture. Polystyrene and carbon dioxide account for approximately 96–98% of the raw materials used. FINNFOAM also contains various additives such as coloring agents, process stabilizers, modifier regulators for the cell structure, etc.

No CFC, HCFC, or HFC gases or fire retardants that contain hazardous bromine compounds are used in the manufacture of FINNFOAM. Neither does FINNFOAM release any gases, particles or fibers that are hazardous to health. FINNFOAM has been rated M1 for emissions, which represents the best quality of indoor air.

STRUCTURE

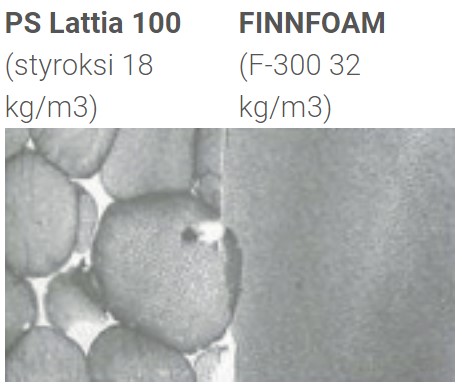

FINNFOAM consists of extruded polystyrene, which is referred to internationally as XPS thermal insulation. The remarkable properties of FINNFOAM are based on its cell structure. FINNFOAM’s cell structure is completely consistent and closed. It is substantially different from the cell structure of expanded polystyrene, i.e., EPS.

FINNFOAM’s completely consistent cell structure is achieved by using a production method in which carbon dioxide is dissolved into molten polystyrene under high pressure. The carbon dioxide is gasified as it is released into regular air pressure from the jet nozzle.

The cells are formed into the desired size and shape using cell structure modifier regulators and the settings of the machine. In the extremely sturdy panels that can withstand more than 70 000 kg/m2 the cells are in a slightly vertical position. More than 23 billion cells can be produced per second.

The manufacturing process also creates a consistent skin on the surface of the panel, which consists of a solid layer of polystyrene instead of cells. This solid skin repels water. The skin on both sides of the panel combines with the cell structure in the middle to create a sandwich structure, which further increases the sturdiness of the panel.

FIRE SAFETY SHEET

CHOISE OF THERMAL INSULATION DOES NOT AFFECT THE FIRE SAFETY OF A BUILDING

Finnfoam Oy has always emphasized the importance of structural fireproofing. The fire safety of a building cannot be affected by thermal insulation and instead it must always be ensured through structural solutions. FINNFOAM does not contain chemical fire retardants, as they are based on bromine, which is hazardous to both the environment and humans. In case of a fire, FINNFOAM does not produce specific toxic gases in addition to carbon monoxide, which means that it is comparable to wood in terms of burning.

The fire safety of a building can mainly be affected through the selection and maintenance of electrical devices, furniture materials and fabrics, and the implementation of an automated extinguishing system. By contrast, the fire safety impact of thermal insulation is minor, because its ignition would require a temperature of 400 °C (at which temperature wood would also ignite). At this point, the inside temperature would have already reached at least 800–1 000 °C.

Finnfoam Oy has had VTT conduct an SBI test in accordance with the European standard conducted. The FINNFOAM material, the fire class of which is undetermined (NPD), achieved a fire rating of B (B-s1, d0) with a less than 3 mm thick combination of cement mortar and fiberglass mesh. For smoke formation, the structure also achieved the highest possible rating -s1, which means that smoke formation was very minor.

When the interior temperature in a fire scenario reaches 300–500 °C, FINNFOAM will melt off the walls (the softening temperature of FINNFOAM is approximately 100 °C and its melting point is below 200 °C) and the rate at which the inside temperature increases will be reduced, because the melting will bind thermal energy and the interior space will no longer be thermally insulated. Using non-melting insulation will result in a completely opposite scenario where the insulation will cause the inside temperature to shoot up to more than 1 000 °C and the fire will become even stronger.

Regardless of the thermal insulation material used, fire walls and barriers should be constructed according to standard practices. This will prevent fire from spreading. The use of stone or slag based thermal insulation for insulating flues is always advisable.